SAFETY AND PERFORMANCE

The Jumbo dispenser is efficient

The Jumbo pallet is handled and positioned using a stacker or forklift. The operator no longer manually transports coils with a standard weight of 19 to 21 kg (no load carrying). In accordance with CSR, Corporate Social Responsibility, using handling equipment reduces the risk of injuries and accidents at work.

- The capacity of a Jumbo dispenser is approximately the length of 3 standard reels depending on the link dimensions. This means 3 times less strapping stop when changing the coil.

- The capacity of an Ultra Jumbo dispenser is approximately the length of 4 Jumbo reels depending on the link size. This means 4 times less strapping stops when changing coils compared to a jumbo coil, or 12 times less stops compared to a standard coil.

The reel

JUMBO is

modular

To facilitate the implementation of the JUMBO SX reel, we have divided it into 2 parts.

The reel mast is positioned in place of a standard reel.

The unwinding part can be moved to the place accessible to the handling device.

The replacement of a standard reel by a JUMBO SX reel is done :

- Without additional electrical communication link

- Independently

- It can be synchronized to the strapping machine using the existing wiring

The use of the JUMBO SX reduces the operator’s movements between the storage area and the strapping station, since he moves to retrieve a whole pallet instead of a coil.

The inside diameters of the Jumbo, ULTRA Jumbo and standard coils are identical(406 mm) .

The Jumbo dispenser accepts standard reels.

Advantages of the Jumbo dispenser

- Positioning of the pallet on the reel with carriage

- Reduced risk of injury to personnel

- No handling of the coil

- Strapping machine loading time: 30s

- Automatically controlled, can be adapted to all strapping machines

- Saves 80% of downtime, coil change and strip loss

- Space saving, 50% storage

- 50% packaging savings

Operation of a JUMBO strip pallet

The operator uses a stacker or forklift to move the Jumbo strip pallet and then places it on the turntable…

Once the pallet has been placed, he removes the chipboard protection plate and releases the first reel from the general plastic film, then removes the protective film around the reel.

The operator then places the aluminium clevis on the top coil which allows to solidify the coils between them and avoids the shift of the coils during the rotation. He will repeat the operation at each reel change.

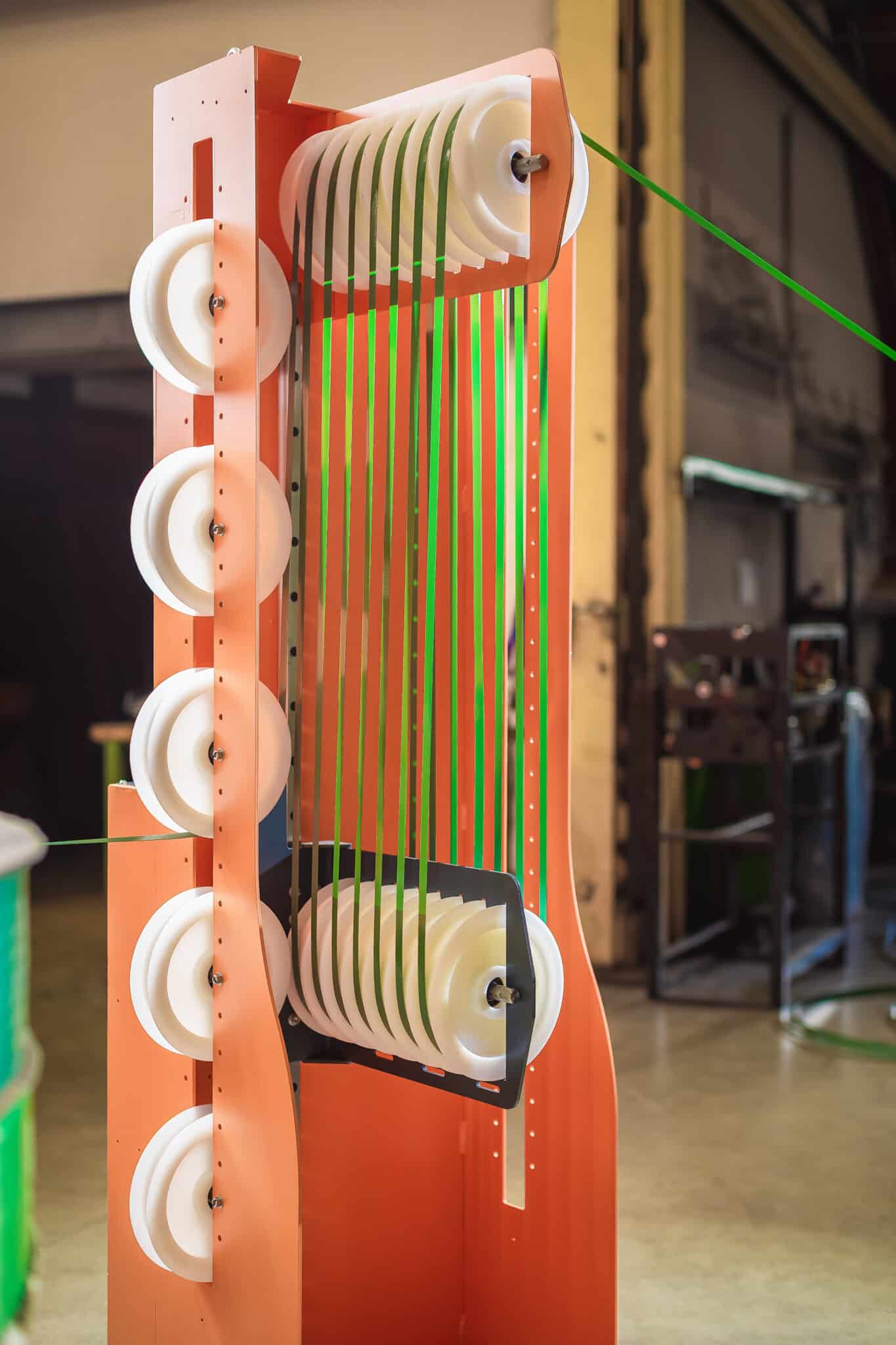

He grabs the end of the strap, triggers the rotation of the plate that unwinds a length of strap and passes the strap into the dedicated pulley, then follows the reeving action on the storage pulleys. Finally, he introduces the strap into the strapping machine.

Technical data JUMBO and ULTRA JUMBO

The JUMBO and ULTRA JUMBO pallets are stackable and have a small footprint, optimizing logistics and storage.

- Jumbo pallet dimensions: 800 x 800 x H 1110 mm to H 1510 mm depending on the number of coils.

- Number of coils: from 5 to 7.

- Average weight of a Jumbo coil: 70 Kg.

- PET and PP strip sizes: from 8 x 0.6 mm to 32 x 1.27 mm.

- ULTRA Jumbo pallet dimensions: 1160 x 1160 x H 1110 mm to H 1400 mm depending on the number of coils.

- Number of coils: from 3 to 4.

- Average weight of an Ultra Jumbo coil: 330 Kg.

- Dimensions PET strips : from 15.5 x 1.00 mm to 32 x 1.27 mm*.

*Note: The production of Ultra Jumbo coils is possible under certain conditions related to the weight of the strip (minimum 17.5 g/meter) and to the order quantities.

Product of

quality

Machine

made to measure

Service &

24-hour repair service

Assistance

24H/24 & 7D/7

Need for

more information?